Ebb,

Replace the asterix in each URL address with an "i" and they should work. It's just the particular designations in the code against profanity that (in this unique case) prevent the page from showing.

What an amazing story. It makes me feel that waiting another six months for "perfect" technical preparations are somehow useless and pointless. "If it 'twere now to die, 'twere now to be most happy..."

:rolleyes:

J.

Replace the asterix in each URL address with an "i" and they should work. It's just the particular designations in the code against profanity that (in this unique case) prevent the page from showing.

What an amazing story. It makes me feel that waiting another six months for "perfect" technical preparations are somehow useless and pointless. "If it 'twere now to die, 'twere now to be most happy..."

:rolleyes:

J.

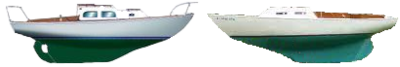

Lastly, I had a 22-lb bruce on my first cruising boat, a Paceship 26, which NEVER ONCE let me down despite that boat's infinitely greated windage.

Lastly, I had a 22-lb bruce on my first cruising boat, a Paceship 26, which NEVER ONCE let me down despite that boat's infinitely greated windage.