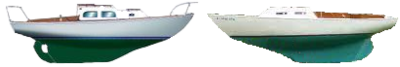

Looks like a nice Commander, only $110!?!?! Yikes!

Bid that sucker Pete, don't let some wannabe run away with it!!!!

Just curious can the slip be transferred? If so how much?

Bid that sucker Pete, don't let some wannabe run away with it!!!!

Just curious can the slip be transferred? If so how much?

?

?