The dilemma around bow pulpits and stern rails is ongoing for me. I have a bow pulpit on Cup O' Tea IV and it's staying there. But the stern....hmmm.

Sometimes when I'm hanging out over the lazarette fussing with the enginge or rigging or something else and the boat is bucking like a bronco on these Long Island Sound waves - it sure does seem desirable.

At 6'3", guidelines are, for me, something to grab pretty late in the game. Probably on the way overboard and too late to do much good. Practically have to bend in half to reach them. That said, for kid sailors they sure do seem desirable.

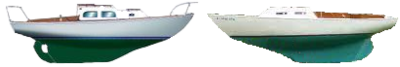

So I went online in search of a pushpit. Found one fairly quickly from those boys up in Maine. But...I just can't pull the trigger. There's something about that clean, open Commander stern that just screams Alberg without the extra hardware putting a period on an otherwise never ending sentence.

Ariels, on the other hand, seem more "established" and welcome the extra chromeware.

Just my 2 cents...

Scott

Sometimes when I'm hanging out over the lazarette fussing with the enginge or rigging or something else and the boat is bucking like a bronco on these Long Island Sound waves - it sure does seem desirable.

At 6'3", guidelines are, for me, something to grab pretty late in the game. Probably on the way overboard and too late to do much good. Practically have to bend in half to reach them. That said, for kid sailors they sure do seem desirable.

So I went online in search of a pushpit. Found one fairly quickly from those boys up in Maine. But...I just can't pull the trigger. There's something about that clean, open Commander stern that just screams Alberg without the extra hardware putting a period on an otherwise never ending sentence.

Ariels, on the other hand, seem more "established" and welcome the extra chromeware.

Just my 2 cents...

Scott