During Atom's first micro-budget circumnavigation I left the original 1/4 plexiglass deadlights as is and bolted 5/8" plywood storm shutters overhanging the outside of the deadlights a few inches and drilled several 1" holes in them for some light and visibility. They were taken off for extended stays in port and stowed under the V-berth and always installed just before every long passage. They were held against the bronze frames by 1/4" machine screws tapped into the bronze. That was the cheapest and fastest way I knew to deal with the problem at the time. I don't recommend it because it was bulky, heavy, and blocked too much light and snagged lines and looked awful.

.

Later I replaced the acrylic with 3/8" polycarbonate, drilled out the tapped frames and thru-bolted them with acorn nuts on the inside. They seem immensely strong now and I don't see any need for storm shutters. No reason you cant use acrylic or polycarbonate external shutters though if you don't feel the deadlights are strong enough. I like to use polycarbonate for most jobs now because it's easier to cut and drill without chipping and cracking than acylic. Tuffak brand is usually much cheaper than Lexan

and has the same properties as far as I know.

James

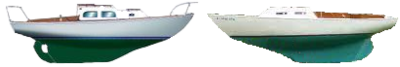

Triton #384 Atom

.

Later I replaced the acrylic with 3/8" polycarbonate, drilled out the tapped frames and thru-bolted them with acorn nuts on the inside. They seem immensely strong now and I don't see any need for storm shutters. No reason you cant use acrylic or polycarbonate external shutters though if you don't feel the deadlights are strong enough. I like to use polycarbonate for most jobs now because it's easier to cut and drill without chipping and cracking than acylic. Tuffak brand is usually much cheaper than Lexan

and has the same properties as far as I know.

James

Triton #384 Atom