Mike wrote -

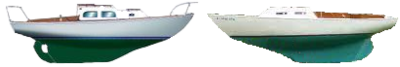

There, another reason to upgrade to a Triton...

QuoteAfter my little foray with the SS23, however, I did become quite infatuated with the function and looks of the fractional rig and spent all last winter with a spreadsheet trying to figure out how to put a Triton mast on an Ariel to add more sail area with a smaller headsail...

There, another reason to upgrade to a Triton...