Hi all,

Well, I have gone over to the dark side. A POWERBOAT? No, no, not that dark. But I have decided that before undertaking the refit on C-231, which I acquired as an interim vessel prior to bringing a 1964 Rhodes Reliant yawl back to life, I should keep an eye out for something more suitable for a family of 5. So I am looking at a Catalina 30 which I can get for next to nothin'.

Is it as pretty as an Alberg design. Heck no, but it makes a lot more sense for myself and 3 sons to cruise Puget Sound on. So I'm putting C-231 on the block. Offering her here first in hopes of finding a quality home for her.

Your can check her out here:

http://www.pearsonariel.org/discussion/showthread.php?2075-Commander-231&daysprune=-1

She is c-231, in case the link does not work, search for the post above.

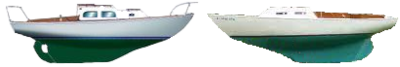

Currently in as acquired condition, sitting on a galvanized trailer pictured toward the end of the post and located on Bainbridge Island, across from Seattle. Been keeping her dry under new tarps since hauling.

Honest assessment of condition: quite good, but ready for a refit and cosmetic upgrade. Especially paint. Decks are SOLID, never had lifeline stanchions, a major source of water ingress, and though I don't care for silicone as bedding material, someone did a good job of getting it in there to seal things up during the boat's mid life in places like the mast base (which was a bear to remove as a result)

This one never had an inboard.

Sails are typical ok older sails, including several headsails.

All standing rigging which came with the boat appears to be original, or at least 30 years old, and though it was rigged when I purchased the boat, I have always intended to replace it simply due to age.

Price:

It came to me cheap, and I'm willing to let it go to a good home just as cheap, even though it is a sound boat, but with some needs.

Boat only without trailer or outboard: $1,800.00

With good running Suzuki DT-8 outboard: $2,000.00

With outboard and trailer: $3,000.00 (best deal, as the trailer could fetch $1500 in a hearbeat)

If purchased with trailer, I will deliver in Puget Sound area.

Title for both boat and trailer are in hand. Trailer tires new in late 2009. Have less than 100 miles on them. Trailer hydraulic brake controller (surge brakes) new in 2010, also seen almost no use.

Well, I have gone over to the dark side. A POWERBOAT? No, no, not that dark. But I have decided that before undertaking the refit on C-231, which I acquired as an interim vessel prior to bringing a 1964 Rhodes Reliant yawl back to life, I should keep an eye out for something more suitable for a family of 5. So I am looking at a Catalina 30 which I can get for next to nothin'.

Is it as pretty as an Alberg design. Heck no, but it makes a lot more sense for myself and 3 sons to cruise Puget Sound on. So I'm putting C-231 on the block. Offering her here first in hopes of finding a quality home for her.

Your can check her out here:

http://www.pearsonariel.org/discussion/showthread.php?2075-Commander-231&daysprune=-1

She is c-231, in case the link does not work, search for the post above.

Currently in as acquired condition, sitting on a galvanized trailer pictured toward the end of the post and located on Bainbridge Island, across from Seattle. Been keeping her dry under new tarps since hauling.

Honest assessment of condition: quite good, but ready for a refit and cosmetic upgrade. Especially paint. Decks are SOLID, never had lifeline stanchions, a major source of water ingress, and though I don't care for silicone as bedding material, someone did a good job of getting it in there to seal things up during the boat's mid life in places like the mast base (which was a bear to remove as a result)

This one never had an inboard.

Sails are typical ok older sails, including several headsails.

All standing rigging which came with the boat appears to be original, or at least 30 years old, and though it was rigged when I purchased the boat, I have always intended to replace it simply due to age.

Price:

It came to me cheap, and I'm willing to let it go to a good home just as cheap, even though it is a sound boat, but with some needs.

Boat only without trailer or outboard: $1,800.00

With good running Suzuki DT-8 outboard: $2,000.00

With outboard and trailer: $3,000.00 (best deal, as the trailer could fetch $1500 in a hearbeat)

If purchased with trailer, I will deliver in Puget Sound area.

Title for both boat and trailer are in hand. Trailer tires new in late 2009. Have less than 100 miles on them. Trailer hydraulic brake controller (surge brakes) new in 2010, also seen almost no use.