Hi All,

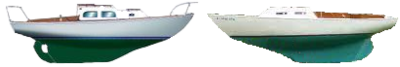

My baby is totaled thanks to incredible incompetence by a hauler and a mooring servicer. Sad days . Basically the deck and the hull are separated on the port side. It's been sitting for a couple years since the incident so it also had a little bit of water on the inside. It's only purpose would be as a parts boat at this point. Just want to make sure no one wants it before I scrap it. You can see some pics of the boat and the work I did in my refurb thread:

. Basically the deck and the hull are separated on the port side. It's been sitting for a couple years since the incident so it also had a little bit of water on the inside. It's only purpose would be as a parts boat at this point. Just want to make sure no one wants it before I scrap it. You can see some pics of the boat and the work I did in my refurb thread:

http://www.pearsonariel.org/discussion/showthread.php?1970-426-Refurb-Rework-Thread&highlight=jurisg

If nothing else, someone should take it just for that rebuilt rudder - i seriously enbeefened that thing...

juris.grauds@gmail.com

6176200511

My baby is totaled thanks to incredible incompetence by a hauler and a mooring servicer. Sad days

. Basically the deck and the hull are separated on the port side. It's been sitting for a couple years since the incident so it also had a little bit of water on the inside. It's only purpose would be as a parts boat at this point. Just want to make sure no one wants it before I scrap it. You can see some pics of the boat and the work I did in my refurb thread:

. Basically the deck and the hull are separated on the port side. It's been sitting for a couple years since the incident so it also had a little bit of water on the inside. It's only purpose would be as a parts boat at this point. Just want to make sure no one wants it before I scrap it. You can see some pics of the boat and the work I did in my refurb thread:http://www.pearsonariel.org/discussion/showthread.php?1970-426-Refurb-Rework-Thread&highlight=jurisg

If nothing else, someone should take it just for that rebuilt rudder - i seriously enbeefened that thing...

juris.grauds@gmail.com

6176200511

Add some countersunk stainless steel straps to reinforce the planks and hardware

Add some countersunk stainless steel straps to reinforce the planks and hardware